黑龍江花崗巖圓錐破碎機,黑龍江破碎生產線

黑龍江哈爾濱花崗巖破碎生產線案例深度報道

項目背景

哈爾濱賓縣賓西鎮作為黑龍江省省級改革試點鎮,充分發揮其得天獨厚的區位優勢與礦產資源儲備優勢:

礦產資源儲量豐富:石灰石(儲量約3億立方米)、建筑用石(儲量近3億立方米)、陶粒頁巖及黏土(總儲量超2億立方米)、鉛鋅礦(已探明儲量1.5億立方米)

交通物流便捷:毗鄰哈爾濱主城區,哈同高速、哈佳鐵路貫穿全境,大宗物料運輸好的

產業政策支持:享受省級工業園區稅收優惠及基礎設施配套補貼

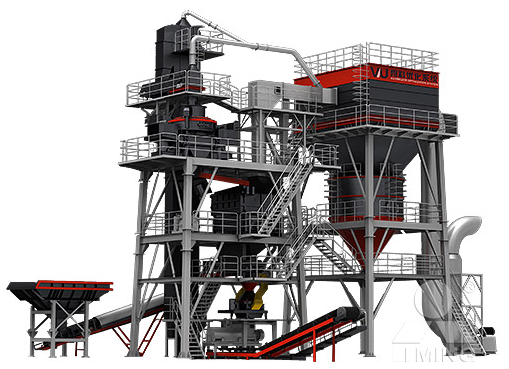

2017年完成的破碎生產線升級改造項目,采用全套液壓圓錐破碎設備,成為東北地區首批實現智能化控制的現代化砂石骨料生產基地,年均供應高品質建筑骨料超200萬噸,服務周邊300公里范圍內的高速公路、鐵路及商混站建設需求。

核心配置

項目 技術參數及配置

加工物料 高硬度玄武巖(抗壓強度180-250MPa,SiO?含量≥45%)

設計產能 400噸/小時(按年作業300天、日運行20小時計,年產能可達240萬噸)

進料要求 ≤800mm原始礦塊(滿足95%以上礦車直接卸載要求)

成品規格 0-5mm(30%)、5-15mm(35%)、15-31.5mm(35%)三檔精品骨料

設備配置

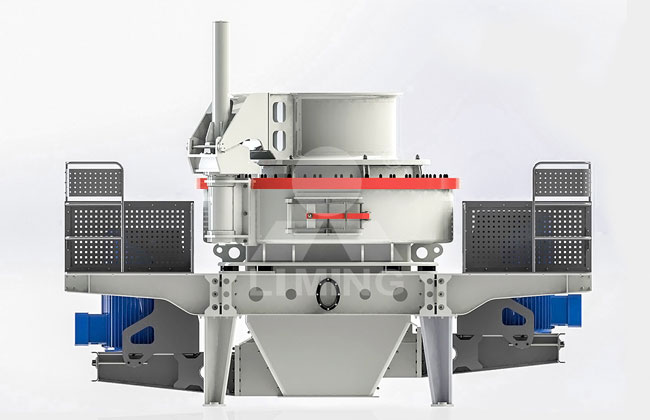

粗碎單元 TSW1345振動給料機(處理能力500t/h)+ HJ125高能顎破(進料口950×1250mm)

中碎單元 HST250S2+HST250H1單缸液壓圓錐破雙機并聯(單機功率315kW,時產180-220t)

細碎單元 HPT300多缸液壓圓錐破(最大通過量320t/h,配備智能排料口調節系統)

篩分單元 2臺3YZS2460圓振動篩(篩網面積14.4㎡,四層篩網配置)

輔助系統 全長680米DTII型皮帶輸送系統(帶寬1200mm,帶速2.5m/s)+ 脈沖布袋除塵系統

工藝流程解析

原料預處理階段

爆破開采后的大塊玄武巖經150噸級礦車運輸至原料堆場

重型板式給料機(TSW1345)實現≤800mm物料均勻給料,配備異物剔除裝置

梯級破碎系統

一級破碎:HJ125顎破通過800t液壓過鐵保護系統,產出≤300mm初級破碎料

二級破碎:雙HST250圓錐破平行作業(可獨立調節腔型),產出≤100mm中間產品

三級破碎:HPT300采用層壓破碎原理,實現成品針片狀含量<10%

智能篩分系統

2臺3YZS2460振動篩構成閉路循環:

上層篩網(31.5mm):超標物料返回HPT300再破碎

中層篩網(15mm):產出路基用粗骨料

底層篩網(5mm):精篩機制砂原料

配備在線粒度分析儀,實時反饋調節破碎參數

環保措施

全封閉鋼架結構廠房(占地12,000㎡)

除塵效率>99%的脈沖布袋系統(排放濃度<20mg/m³)

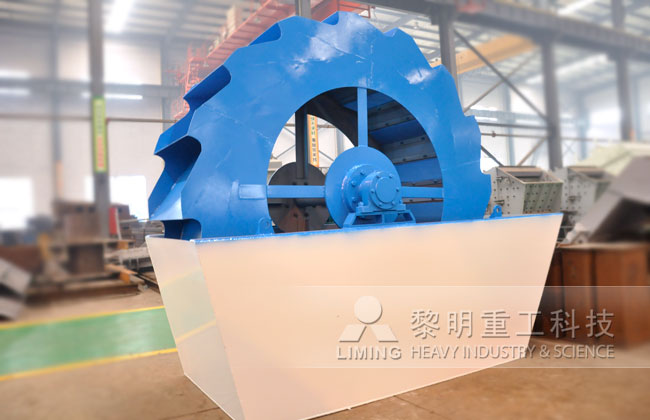

循環水洗砂系統(水資源利用率達85%)

技術創新亮點

液壓系統集成

全生產線采用統一液壓站供能,比傳統彈簧圓錐破節能18-22%

HST單缸機配備ACC智能控制模塊,排料口調整精度±1mm

耐磨件優化

破碎壁/軋臼壁采用Mn18Cr2高錳鋼+碳化鎢復合襯板,使用壽命提升至3800小時

智能運維系統

云平臺遠程監控實現:軸承溫度預警、潤滑油污染度檢測、振動頻譜分析

該生產線累計處理玄武巖超1200萬噸,設備綜合運轉率≥92%,成為東北地區綠色礦山的典范案例。其"顎破+雙圓錐破+多缸破"的配置模式,已成功復制到遼寧省5個同類項目中。

哈爾濱破碎生產線阿城道外破碎生產線哈爾濱市平房區破碎生產線黑龍江花崗巖圓錐破碎機

黑龍江花崗巖圓錐破碎機破碎生產線,該產品是由黑龍江花崗巖圓錐破碎機器制造哈爾濱市平房區分公司黑龍江花崗巖圓錐破碎機石機器制造廠砂石破碎生產線排行榜巴彥破碎生產線立軸破制砂機1250型生產線哈爾濱小型破碎機 哈爾濱晶制造有限公司制砂破碎生產線設備碩集公司年產80萬噸砂石生產線哈爾濱道外區超達玻璃機器加工廠山東機制砂生產線設備生產廠家

Henan LIMING Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipments was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. The Headquarter is located in HI-TECH Industry Development Zone of Zhengzhou and covers 80000 m ². Another workshop in Shangjie Industry Park covers 67000 m ². Over the more than 30 years, our company adheres to modern scientific management system, precision manufacturing, pioneering and innovation. Now LIMING has become the leader in domestic and oversea machinery manufacturing industry.

LIMING brings a large number of high-qualification talents together. Bai Yinghui, general research and development engineer, is a well-known expert in crushing and grinding area who won the youth medal of technology of the state council and receives special government allowance. LIMING owns an experienced service team, offering the customer free design and professional skill training and live guide for installation and debugging. The company's service networks have spread all over the country. Established client files, and mix the traditional door-to-door service with online service together, complementary the advantages. LIMING has won high recognition from clients.

The company mainly manufactures mobile crushers, stationary crushers, sand-making machines, grinding mills and complete plants that are widely used in mining, construction, highway, bridge, coal, chemical, metallurgy, refractory matter, etc. Product quality is life, and scientific innovation is motive power. LIMING got ISO international quality system certification, European Union CE certification and Russian GOST certification. The company has strong research and development strength and innovation.

LIMING machinery research institute was founded in 2005 which is the most powerful comprehensive technological research institute in the domestic mining machinery industry and provides top scientific research platform for professional personnel. Up to now, LIMING has won 10 national patents, 24 national utility model patents and 3 provincial science and technology achievement awards. The company products remain the international leading level by strengthening international exchanges and cooperation all the time, and has won a wide range of international market, such as Russian, Azerbaijan, Kazakhstan, Turkey, Kuwait, South Africa, Egypt, Vietnam, Malaysia, India, Australia, Korea, Canada and European Union,etc. Through more than 30 years' hard work, LIMING's staff built supremacy of credibility, excellent quality, service "LIMING" brand, and has made outstanding contributions to the development of mechanical manufacturing industry for China and the whole world.

LIMING machinery research institute was founded in 2005 which is the most powerful comprehensive technological research institute in the domestic mining machinery industry and provides top scientific research platform for professional personnel. Up to now, LIMING has won 10 national patents, 24 national utility model patents and 3 provincial science and technology achievement awards. The company products remain the international leading level by strengthening international exchanges and cooperation all the time, and has won a wide range of international market, such as Russian, Azerbaijan, Kazakhstan, Turkey, Kuwait, South Africa, Egypt, Vietnam, Malaysia, India, Australia, Korea, Canada and European Union,etc. Through more than 30 years' hard work, LIMING's staff built supremacy of credibility, excellent quality, service "LIMING" brand, and has made outstanding contributions to the development of mechanical manufacturing industry for China and the whole world.

現場視頻如下:

應用方案

應用方案